The Gustav Eirich Award

The aim of this award is to promote ideas and, at the same time, to support young talents in technical disciplines.

The aim of this award is to promote ideas and, at the same time, to support young talents in technical disciplines.

The Gustav Eirich Award is a contribution to the long-term success of companies in the refractories production and application industries.

The Gustav Eirich Award is presented for the three best dissertations (Ph.D. theses) or equivalent work in the field of refractories that have been completed no longer than two years ago.

Applications for the 2024 Gustav Eirich Award are invited until 31st May 2024. To apply, please see the "Guidelines for application" below.

The 2024 Gustav Eirich Award will be presented during the “International Colloquium on Refractories” ICR on 18 September 2024 in Aachen, Germany.

Guidelines for application

To apply for the Gustav Eirich Award, please submit:

- A curriculum vita (use this template)

- A copy of your Ph.D. certificate, which shows the date you were awarded your Ph.D.

- An abstract of your Ph.D. thesis according to the following rules:

- Max. 4 pages

- English language

- A4 or letter format

- Font size not smaller than 10 pt

- Please submit all documents as individual PDF files. You may bundle them into a ZIP archive if you wish.

Members of the evaluation panel

The economy is represented on the jury by:

- Manuel Miranda Martinez, IDONIAL, Spain

- Thomas Auer, Böhler Edelstahl GmbH, Austria

- William L Headrick Jr PhD, RHI Magnesita, USA

The science is represented on the jury by:

- Dr. Patrick Gehre, TU Bergakademie Freiberg, Germany

- Prof. Marc Huger, ENSCI Limoges, France

- Prof. Jacek Szczerba, AGH Dept. f. Ceramics & Refractories, Poland

Organisers

- Stephan Eirich, Maschinenfabrik Gustav Eirich GmbH & Co KG, Germany

- Dr. Christian Dannert, ECREF European Centre for Refractories gem. GmbH, Germany

List of former winners

Dr. Audrey Tixier

Ecole des Mines Saint-Etienne, France

"Formulation and modelling of the shaping of SiC refractory tiles for waste-to-energy facilities"

2nd Prize

Dr. Maciej Ludwig

AGH University of Science and Technology, Poland

"Recycled aggregate as raw material in MgO-C technology"

3rd Prize

Dr. Dominik Hahn

Universität Koblenz, Germany

"Structural analysis of phosphate-bonded Al2O3-MgAl2O4-high-temperature ceramics"

1st Prize

Dr. Johannes Kasper

Universität Koblenz-Landau, Germany

"Setting models for PCE-dispersed and calcium-aluminate-cement-bonded refracory castables"

2nd Prize

Dr. Diana Vitiello

University of Limoges, France

"Thermo-physical properties of insulating refractory materials"

3rd Prize

Dr. Jakub Stec

AGH University of Science and Technology, Poland

"3-D pore structure and infiltration resistance of micropore carbon materials"

1st Prize

Dr. Lise Loison

RWTH Aachen University, Germany

High temperature corrosion of calcium hexa-aluminate with biomass slag

2nd Prize

Dr. Imad Khlifi

University of Limoges, France

Optimisation of optical methods for strain field measurments dedicated to the characterisation of the fracture behaviour of refractories: Application to magnesia based materials

3rd Prize

Dr. Fangguan Tan

Wuhan University of Science and Technology, Wuhan, China

Study on failure and refining effect of purging plug with different slits

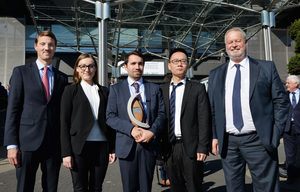

Andreas Hermann (ECREF)

Stephan Eirich

Dr. Andrzej Warchal (1st prize)

Dr. Stephan Clasen (2nd prize)

Dr. Fu Lvping (3rd prize)

Dr. Christian Dannert (ECREF)

Thomas Seger

1st Prize

PhD Andrzej Warchal

Université de Limoges, France

Study of the Influence of additives (antioxidants) on the thermomechanical properties of carbon-bonded refractory composites.

2nd Prize

Dr. rer. nat. Stephan Clasen

Universität Koblenz Landau, Germany

Contribution to analysis and understanding of molten steel infiltration into the gas purging slits of gas purging plugs

3rd Prize

Dr. Fu Lvping

Wuhan University of Science and Technology, Wuhan, China

Design, fabrication and application of lightweight alumina used for wear lining materials

Dipl.-Betriebswirt Thomas Seger

Prof. Dr. Dr.h.c. Peter Quirmbach

Dr. Xiong Liang

Dr. IIlona Jastrzebska

Dr. José Ramón Campello Garcia

Dipl.-Ing. Stefan Eirich

1st Prize

Dr. José Ramón Campello Garcia

University of Oviedo, Fundación ITMA, Llanera, Spain

Development of Söderberg carbon electrodes bonded with a carbon nanofiber reinforced coal-tar pitch

2nd Prize

Dr. IIona Jastrzebska

Department of Ceramics and Refractories, AGH University of Science and Technology, Krakow, Poland

Hercynite solid solutions Synthesis, Properties and Applications

3rd Prize

Dr. Xiong Liang

The Key State Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology, Wuhan, PR China

The design of three-layered struts to strengthen SiC reticulated porous ceramics for porous media combustion

1st Prize

Adrian Villalba Weinberg, PhD

Ecole des Mines de Saint-Etienne and CEMHTI-CNRS Orléans, France

Understanding the failure and development of innovative refractory materials for hazardous waste incinerators

2nd Prize

Edyta Sniezek, PhD

Faculty of Materials Science and Ceramics, AGH University of Science and Technology

Magnesia-zirconia refractory materials with aluminate phases

3rd Prize

Junfeng Chen, PhD

The Key State Laboratory of Refractories and Metallurgy, Wuhan University of Science and Technology

The microstructure design of the bonding system and novel technical routes for Si3N4 bonded SiC refractories

Prof. Dr. Peter Quirmbach

Dr. Qinghu Wang

Dr. Nora Brachold

Dr. Younes Belrhiti

Dr. Andreas Seiler

1st Prize

Dr. Nora Brachold

Technische Universität Bergakademie Freiberg

Alkali corrosion resistant heat insulation materials

2nd Prize

Dr. Younes Belrhiti

University of Limoges / CNRS SPCTS

Strain Field measurements: novel engineering approach to enrich the characterization of Refractories with non-linear mechanical behavior

3rd Prize

Dr. Qinghu Wang

Wuhan University of Science and Technology

Development of Novel Carbon Sources of strengthen and toughen Carbon containing Refractories

Prof. Dr. Peter Quirmbach

Prof. F. Golestani

(as representative for Dr. Khezrabad)

Romain Boigelot

Dr. Marcus Emmel

Dr. Christoph Heynen

1st Prize

Romain Boigelot, PhD

Université d'Orléans, CEMHTI, UPR3079 CNRS, Orléans, France

Corrosion of high alumina castables by liquid ashes during the gasification of sewage sludge

2nd Prize

Dr. Marcus Emmel

Technical University of Freiberg, Institute of Ceramic Glass and Construction Materials, Freiberg, Germany

Development of Active and Reactive Carbon Bonded Filter Materials for Steel Melt Filration

3rd Prize

Dr. Nouri Khezrabad

Iran University of Science and Technology, School of Metallurgy and Materials Engineering, Tehran, Iran

Novel Engineering Route to Improve the Green Mechanical Properties of Nano-Bonded Refractory Castables

Dipl.-Ing. Stefan Eirich

Dipl.-Ing. (FH) Jörg Zimmermann

Dr. Rudy Michel

Dr. Dominika Madej

Prof. Dr. Peter Quirmbach

1st Prize

Dipl.-Ing. (FH) Jörg Zimmermann

Forschungsgemeinschaft Feuerfest, Höhr-Grenzhausen, Germany

Development of an innovative unshaped refractory castable for the application in the slag runner of cupola furnaces

2nd Prize

Dr. Dominika Madej

AGH, University of Science and Technology, Krakau, Poland

Corrosion of Al2SiO5-SiC and Al2SiO5-ZrSiO4 refractories in the corroding medium of the external heat exchanger of cement kiln

3rd Prize

Dr. Rudy Michel

CNRS-CEMHTI, Orléans, France

Behaviour of olivine refractories: agglomeration of fluidized bed reactor and interaction with Al-killed steel

Dr. Christoph Heynen

Tiago M. Souza, Ph.D.

Dipl.-Ing. Patrick Gehre

Dr. Bai Cui

Prof. Dr. Peter Quirmbach

1st Prize

Dipl.-Ing. Patrick Gehre

TU Bergakademie Freiberg, Freiberg, Germany

Possible desing of chrome oxide free refractory castables with corrosion resistance against molten coal slag for use in slagging gasifiers

2nd Prize

Tiago M. Souza, Ph.D.

Federal Unirversity of Sao Carlos, Brazil

Novel Technological Route to Overcome the Challenging Magnesia Hydration of Cement-Free Alumina Castables

3rd Prize

Dr. Bai Cui

University of Illinois at Urbana-Champaign, USA

Microstructural Evolution and Oxidation Behaviour of Spark Plasma Sintered Mn+1AXn Ceramics

Dipl.-Ing. Stefan Eirich

Jinichiro Nakano, Ph.D.

Dipl.-Ing. Volker Stein

Rafael Guimaraes de Sa, Ph.D.

Dipl.Bw. Thomas Seger

1st Prize

Jinichiro Nakano, Ph.D

National Energy Technology Lab / URS, Albany, USA

A comprehensive study of modern gasification slags and refractory used in gasifiers to guide the development of novel/improved lining materials.

2nd Prize

Dipl.-Ing. Volker Stein

TU Bergakademie Freiberg, Freiberg, Germany

Contribution for the Characteristic Improvement of Carbon Bonded Doloma Refractories by addition of TiO2r

3rd Prize

Rafael Guimaraes de Sa, Ph.D.

Department of Materials of Imperial College, London , UK

In-situ and ex-situ incorporation of carbon nanostructures into ceramiccarbon-metal nanocomposites

Dipl.Bw. Thomas Seger

Dipl.-Ing. Christian Brüggmann

Dr. Franz Melcher

M.Sc. Vasileios Roungous

Dipl.-Ing. Stefan Eirich

1st Prize

M. Sc. Vasileios Roungous

TU Bergakademie Freiberg, Freiberg, Germany

Prospects of developing self glazing AI2O3-C refractories for monobloc stopper applications

2nd Prize

Dr. Franz Melcher

TREIBACHER INDUSTRIE AG, Althofen, Austria

Experimental studies of the influence between different ladle slags and refractory wear inside of ladles and RH-degasser

3rd Prize

Dipl.-Ing. Christian Brüggmann

Forschungsgemeinschaft Feuerfest e.V., Bonn, Germany

Contribution to the slagging of MgO in secondary metallurgical slags

Dr. Wolfgang Schärfl

Dr. Marina Braulio

Dr. Robert Sauerbrey

1st Prize

Dr. Mariana Braulio

Federal University of Sao Carlos, Materials Microstructural Engineering Group-GEMM, Sao Carlos, Brazil

Novel engineered routes for advanced Al2O3-MgO refractory castables

2nd Prize

Dr. Robert Sauerbrey

Technology Center, RHI AG, Leoben, Austria

Corrosion behavior of refractory materials in slags under the influence of electric fields

3rd Prize

Dr. Wolfgang Schärfl

TU Bergakademie Freiberg, Institute of Ceramic, Glass and Construction Materials, Freiberg, Germany

Thermal shock resistant alumina based disel soot particulate filters (dpf)